ECOPTIK can process custom-sized high-precision polarizing lenses to meet customers' requirements for highly reflective media or media + metal coating.

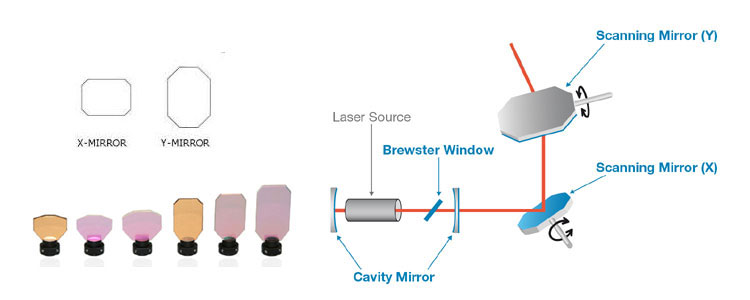

The base material of the vibrating lens is usually H-K9L glass, fused silica, quartz and monocrystalline silicon, which is used in the interior of the vibrating lens system. The other working principle is that the expanded laser beam is incident on the X and Y vibrating lenses, and the reflection angle of the vibrating lenses is controlled by software, so that the two vibrating lenses are offset along the X and Y axis respectively, so as to achieve the deflection of the laser beam.

Advantage:

Fastest motor speeds in the industry, delivering low drift and long-term stability

Superior precision and accuracy that ensure high-quality scanning output

Extensive range of aperture sizes and mirror coatings

Compact models with small footprint ensure easy integration for small spaces

Broad range of product offerings from high-performance to cost-effective

LXW Tolerance: +0/-0.1

Clear Aperture: >90%

Thickness Tolerance:+/-0.1mm

Surface Quality:40/20

Surface Figure: lambda/425mm2(at)632.8nm

266nm | Fused silica | Aluminum Reflector Coating |

10.6um | Si | Gold Reflector Coatings |

1064nm/650nm/532nm | Si/BK7 | Dielectric Reflector Coating |