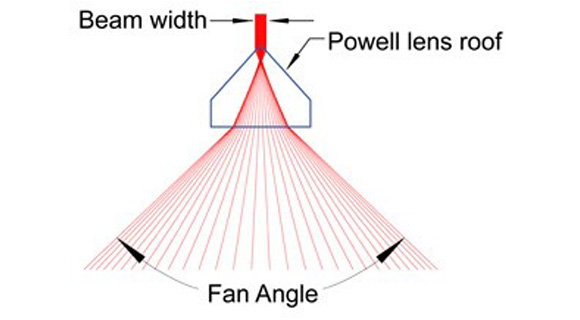

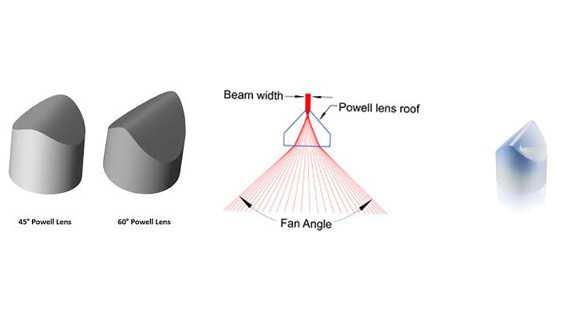

The Powell lens is a quantum leap forward in line generator performance over the simple cylinder lens. A cylinder lens produces a poorly illuminated line, one limited by the non-uniform, Gaussian laser beam. The Powell lens' rounded roof is in fact a complex two-dimensional aspheric curve that generates a tremendous amount of spherical aberration that redistributes the light along the line; decreasing the light in the central area while increasing the light level at the line's ends. The result is a very uniformly illuminated line used in all manner of machine vision applications; from bio-medical and automobile assembly to chocolate chip cookie production.

Powell prism (also known as laser linear generator lens) is an optical marking prism, which can be optimized for the input of laser beam with the diameter of 0.8mm. Powell optical prism makes the laser beam can be optimized into a straight line with uniform optical density, good stability and good linearity after passing through. Different from the cylindrical lens which produces the characteristics of central hot spot and faded edge gaussian beam, it can eliminate the distribution of central hot spot and faded edge of gaussian beam and form a straight line with uniform energy distribution. The full fan Angle ranges from 1° to 120°. The standard specifications are 5°, 10°, 20°, 30°, 40°, 45°, 50°, 60°, 70°, 80°, 90°, 110° and 120°.

Gaussian laser beam by ordinary cylindrical lens, produces the uneven distribution of straight line, and Powell at the top of the prism is complex two-dimensional aspheric surface, through laser will produce a large number of spherical aberration, light path is redistributed, reduce the light of the central region, increase the edge of the light, to form a uniform line, suitable for all kinds of biological medicine, automobile assembly, food processing and machine vision applications.

Used for positioning, laser marking machine, processing marking positioning, marking the building target, laser scanning system, measuring equipment. For a variety of machine vision applications; From biomedical to automotive assembly to chocolate chip cookie production; Mobile phone all kinds of online detection, aircraft military applications, ship plant.

| Material | Fused silica/ BK7glass |

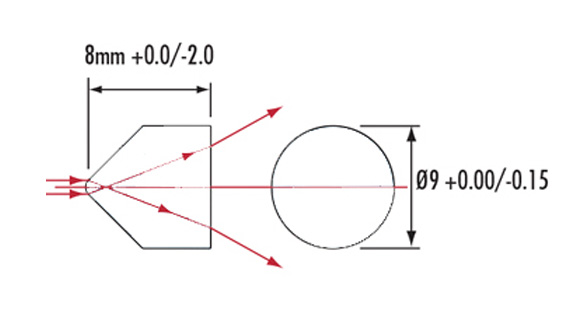

| Diameter | Φ0.8mm, Φ1mm, Φ2mm, Φ3mm, Φ5mm, Φ9mm, Φ10mm, Φ 15mm or customized size |

| Diameter Tolerance | +0.0/-0.05mm / ±0.05mm |

| Range of Fan | 3°,5°,10°,15°,20°,30°,45°,53°,60°,70°,75°,85°,90°96°,100°,110°,120° |

| Angle tolerance | <3arc min~30arc sec. |

| Beam wide | 3mm, 4mm, 5mm or customized size |

| Surface quality | 60/40, 40/20, 20/10 scratch and dig |

| Clear aperture | >90% |

| Bevel | <0.2mm×45° |

| Coating | As per customer’s request |

| Type No. | Beam dimension (mm) | Angle of fan ( °) | Diameter ( mm ) | Height ( mm ) |

| BRD-PWP-1GB-15 | 1 | 15 | 9 | 8 |

| BRD-PWP-1GB-30 | 1 | 30 | 9 | 8 |

| BRD-PWP-1GB-40 | 1 | 40 | 9 | 8 |

| BRD-PWP-1GB-45 | 1 | 45 | 9 | 8 |

| BRD-PWP-1GB-60 | 1 | 60 | 9 | 8 |

| BRD-PWP-1GB-90 | 1 | 90 | 9 | 8 |

| BRD-PWP-1GB-110 | 1 | 110 | 9 | 8 |

| BRD-PWP-2GB-4 | 2 | 4 | 9 | 8 |

| BRD-PWP-2GB-30 | 2 | 30 | 9 | 8 |

| BRD-PWP-2GB-60 | 2 | 60 | 9 | 8 |

| BRD-PWP-2GB-70 | 2 | 70 | 9 | 8 |

| BRD-PWP-2.5GB-30 | 2.5 | 30 | 9 | 8 |

| BRD-PWP-3GB-10 | 3 | 10 | 9 | 8 |

| BRD-PWP-3GB-15 | 3 | 15 | 9 | 8 |

| BRD-PWP-3GB-20 | 3 | 20 | 9 | 8 |

| BRD-PWP-3GB-30 | 3 | 30 | 9 | 8 |

| BRD-PWP-3GB-45 | 3 | 45 | 9 | 8 |

| BRD-PWP-3GB-60 | 3 | 60 | 9 | 8 |

| BRD-PWP-3GB-70 | 3 | 70 | 9 | 8 |

| BRD-PWP-3GB-90 | 3 | 90 | 9 | 8 |

| BRD-PWP-3GB-110 | 3 | 110 | 9 | 8 |

| BRD-PWP-4GB-22 | 4 | 22 | 9 | 8 |

| BRD-PWP-4GB-30 | 4 | 30 | 9 | 8 |

| BRD-PWP-4GB-90 | 4 | 90 | 9 | 8 |

| BRD-PWP-5GB-10 | 5 | 10 | 9 | 8 |

| BRD-PWP-5GB-30 | 5 | 30 | 9 | 8 |

| BRD-PWP-5GB-35 | 5 | 35 | 9 | 8 |

| BRD-PWP-5GB-40 | 5 | 40 | 9 | 8 |

| BRD-PWP-5GB-45 | 5 | 45 | 9 | 8 |

| BRD-PWP-5GB-55 | 5 | 55 | 9 | 8 |

| BRD-PWP-5GB-60 | 5 | 60 | 9 | 8 |

| BRD-PWP-5GB-70 | 5 | 70 | 9 | 8 |

| BRD-PWP-5GB-75 | 5 | 75 | 9 | 8 |

| BRD-PWP-5GB-90 | 5 | 90 | 9 | 8 |

| BRD-PWP-5GB-110 | 5 | 110 | 9 | 8 |

| BRD-PWP-5.7GB-90 | 5.7 | 90 | 9 | 8 |