With the development of modern optics, cylindrical power lens elements are being increasingly applied in optical systems. In this article, we will provide a detailed introduction to the characteristics of cylindrical elements, cylindrical power lens center deviation definition and testing methods to familiarize you with this relatively special element, so as to better apply it in practice.

A cylinder is the surface cut vertically from the outside of a cylinder. It has an arc radius in one direction, and its sectional line is an arc, while in the perpendicular direction, the curvature is infinite, meaning the sectional line is a straight line. Commonly referred to as the cylindrical power lens, one of its sides is cylindrical, and the other surface is either planar or spherical.

Because cylindrical mirrors have the characteristics of converging and diverging light beams in a single direction, they are widely used in linear beam shaping applications. For example, the barcode scanning devices we often see use cylindrical power lens. Common applications also include movie projection, fax machines, medical imaging, automotive imaging, and laser shaping, all of which feature cylindrical mirrors.

In addition to the common plano-convex, plano-concave, bi-convex, or bi-concave poweres, with the progress of optical manufacturing technology, cylindrical aspheric poweres are also gradually being applied in practice. The cylindrical section line of these products is an aspheric curve, allowing for better imaging performance in optical systems.

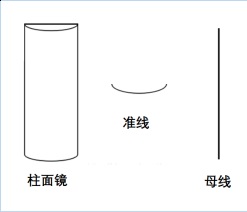

Let's first understand the concepts of the generatrix and directrix of a cylinder. A cylinder can be seen as a surface formed by moving a straight line parallel to a given arc line. The straight line is called the generatrix of the cylinder, and the arc surface is called the directrix of the cylinder, as shown in the figure below:

In the manufacture of cylindrical mirrors, manufacturing errors are unavoidable, causing deviations when viewed from various directions. For example, when viewed from the non-arc direction, ideally, the generatrix of the cylindrical surface is parallel to the back plane. However, due to manufacturing errors, there is usually a certain wedge angle between the generatrix of the cylinder and the back plane.

In the arc direction, ideally, the edges on both sides of the arc surface are of equal height relative to the back plane. In practice, there may be cases of unequal thickness, indicating a certain deviation of the arc surface.

Additionally, in the manufacture of cylindrical power lens, non-parallelism may exist between the generatrix of the cylinder and the two side planes. The actual generatrix deviates by a certain angle from the ideal generatrix, calledTwist. This error also affects the actual performance of the power lens.

In summary, the center deviation of cylindrical mirrors can exist in multiple forms. Therefore, it is necessary to adopt appropriate methods to test their center deviation. The testing methods for cylindrical power lens center deviation include commonly used dial indicator methods, laser irradiation methods, and autocollimation inspection methods.