With the iterative development of unmanned driving technology and the continuous improvement of technical requirements, optical tubes were born as radar and sensor protection devices.

First, it is introduced that a quartz tube is processed by an optical cold working process, which fully ensures that the inner and outer walls are basically the same thickness, and the tolerance is controlled within ±10um. At the same time, in order to support the AR coating, the transmittance is more fully guaranteed. It can realize 360° all-round detection without dead angle, which will make the detector of driverless car more three-dimensional and comprehensive.

| Material | Fused silica (Quartz) |

| Outer diameter | 300mm |

| Wall thickness | 5mm |

| Wall thickness tolerance | ±10um |

| Height | 300mm |

| Surface quality | 60/40 Scratch/Dig |

| Surface roughness | <50A outer surface |

| <100A inner surface | |

| Coating | AR Coating@ 1550nm R≤1% for outer cylinder surface |

| Bevel | 0.25mm x 45deg Max. |

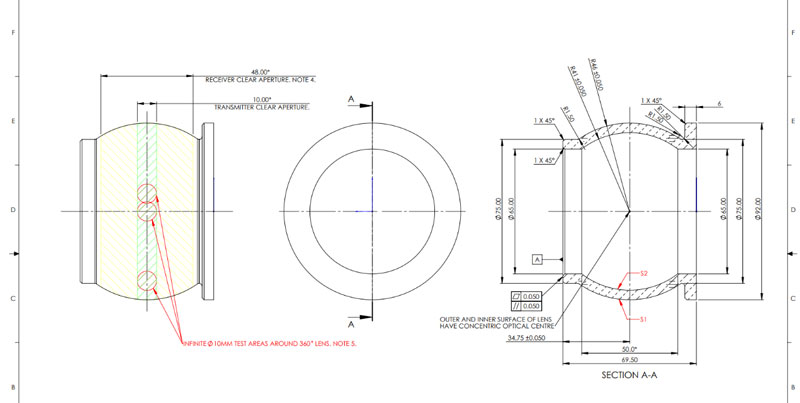

The second is a custom-made tube that differs from the first in that its surface is a sphere rather than a cylinder. As shown in Figure 1, its outer surface and inner surface are two parallel surfaces, and the two equal thickness surfaces ensure that the optical path or image will not be distorted. Both ends are custom designed, mainly based on the needs of the assembly.