The scanning function of laser galvanometer is widely used in all kinds of laser processing technology, especially in the marking process. Let's discuss the study of galvanometer mirror working principle and application.

The principle of the galvanometer is: input a position signal, the oscillating motor (laser galvanometer) will swing a certain Angle according to a certain voltage and Angle conversion ratio. The whole process adopts closed-loop feedback control, which is operated by position sensor, error amplifier, power amplifier, position divider, current integrator and other five control circuits. The principle of digital laser galvanometer is to convert analog signals into digital signals on the principle of analog laser galvanometer.

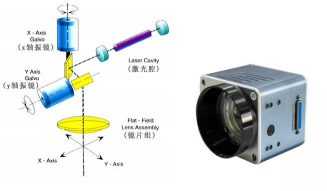

Application of galvanometer in marking industry: Galvo scanner marking head is mainly composed of XY scanning mirror, field mirror, galvanometer and computer-controlled marking sof ware. Select the corresponding optical components according to the different laser wavelengths. Related options also include laser beam expander, laser, etc. Lasers can mark paper, metal, plastic, and countless other materials.

The working principle is: The laser beam is incident on the two mirrors (scanning mirrors), and the reflection Angle of the mirrors is controlled by the computer. The wo mirrors can be scanned along the X and Y axes respectively, so as to achieve the deflection of the laser beam, so that the laser focus with a certain power density moves on the marking material according to the required requirements, leaving a permanent mark on the surface of the material. The focused light spot can be circular or rectangular, and in the galvanometer scanning system, vector graphics and text can be used.

The application of the galvanometer scanning system in the field of laser soldering: The working principle of the galvanometer is the same as that in marking applications. By deflecting the angle of the two galvanometers on the X and Y axes, the laser beam is reflected onto the processing surface through the beam expanding mirror. The range of the galvanometer reflecting the laser onto the processing surface is the galvanometer scanning range, and the welding points and laser spots within this processing range can be effectively heated, The laser spot movement required for different welding points can be achieved without relying on a two-dimensional mobile platform. Because the deflection speed of the galvanometer is very fast, the laser spot movement be ween various solder joints is also very fast, far exceeding the movement speed of the conventional wo-dimensional moving axis. Under the premise of pre coating solder paste, this high-speed moving laser spot function can greatly improve the welding speed.

Laser galvanometer systems can also be used in laser drilling, welding, cutting, cleaning, biomedical and ophthalmic diagnostics.The use of galvanometer band is usually: ultraviolet (355nm), green (532nm), infrared band (1064, 1070, 10.6um) and so on.